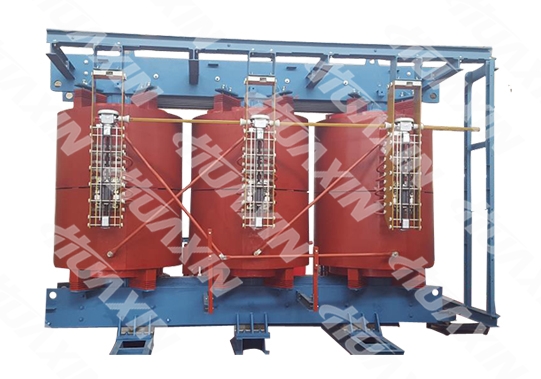

35KV SCB10 Series Epoxy Resin Casting Dry-type Distribution Transformer

The 35KV SCB10 Series Epoxy Resin Casting Dry Type Distribution Transformer is suitable for special electricity occasions with direct conversion from 35kV electricity grid voltage to 400V. Compared with 6 to 10kV distribution transformer, this type of transformer has higher requirements for product manufacturing. Therefore, the unique transformer casting local discharge control technology and internal stress control process are adopted to control the internal insulation at the most ideal state, so as to guarantee key performance of the transformer.

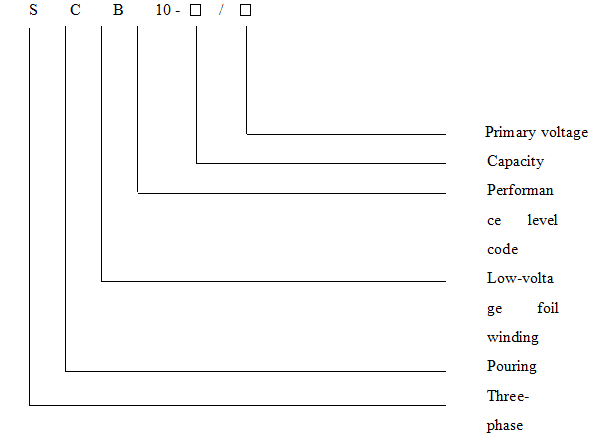

Model Description

Technical Parameters

Rated

Capacity

(KVA)

Voltage Combination

Connection

Unit Symbol

Idle Load Loss (W)

Load Loss 155℃ (W)

No-load

Current (%)

Short-circuit Impedance (%)

High-voltage (KV)

Tapping (%)

Low-voltage (KV)

800

35

±2×2.5 ±5

3.15 6 6.3 10 10.5 11

Dyn11 Yd11 Y yn0

2250

9100

0.95

6

1000

2670

10900

0.95

1250

3130

12900

0.85

1600

3690

15400

0.85

2000

4230

18200

0.75

7

2500

4860

21800

0.75

3150

6030

24500

0.7

8

1. The high-quality cold rolled oriented silicon steel sheet is selected for the iron core, which has 45° fully beveled seam and five-step folding iron mode. Both the core column and the iron yoke have the multi-stage round section shape, low no-load loss and low noise can be obtained.

2. According to the transformer capacity, the flat copper wire wrapped with double glass paints is adopted as the high-voltage conductor, and Grade H glass fiber cloth and glass felt are adopted for inter-laminar insulation. The low-voltage conductor is wounded with copper foil, epoxy resin prepreg cloth is adopted for inter-laminar insulation. Both of them have very high mechanical strength and resistance to sudden short circuit.

3. The coordination structure between the low magnet steel pulling plates and clamps is adopted, sand blasting and plastic spraying are conducted, and the overall structure is artistic and has high mechanical strength.

4. Each phase is equipped with the independent axial flow blower and split-type thermostat, which can effectively reduce temperature rise, improve transformer output capacity, and guarantee safe operation of the transformer.

Rated Capacity (KVA)

Dimensions (mm) L × W × H

Weight (kg)

800

1000

1250

1600

2000

1915×1320×1750

4800

2500

3150

1. Safe, fire-proof and pollution-free. It can be directly operated at the load center.

2. Adopting the HTT technology from Germany. with high mechanical strength, strong anti-short circuit capacity, small local discharge and good thermal stability.

3. Small volume, light weight, less space occupying and convenient installation

4. Low loss, low noise, maintenance-free and remarkable energy-saving effects

5. Damp-proof, mildew proof, salt fog proof, good heat dissipation, suitable for operation at high elevation, high humidity and other harsh environments

1. The elevation shall not exceed 1000m

2. Ambient temperature Maximum temperature +40℃/+104oF

Maximum daily average temperature +30℃/+86oF

Maximum annual average temperature +20℃/+68oF

Minimum temperature -30℃ / -22 oF (applicable for the outdoor transformer)

Minimum temperature -5℃/+23oF (applicable for the indoor transformer)

3. The waveform of the supply voltage is similar to a sine wave

4. The supply voltage connected with the multi-phase transformer shall be approximately symmetrical.

Case studies

Contact information

-

About Huaxin

-

Follow Us

-

Share Us

©1996-2017 晉ICP備07500050號(hào) Huaxin Copyright

©2016-2017 晉ICP備07500050號(hào) Huaxin Copyright